Product quality and safety are the most important prerequisites for Henkaul, our comprehensive quality control by manual inspection and inspection machines on account of we accept specifically tailored production and small batch sizes. our continuous improvement strategy, which relies on committed employees and numerous activities aimed to reach our goal of zero defects in all our processes.

Bent or Crooked Finish: A finish which has a bent or crooked appearance.

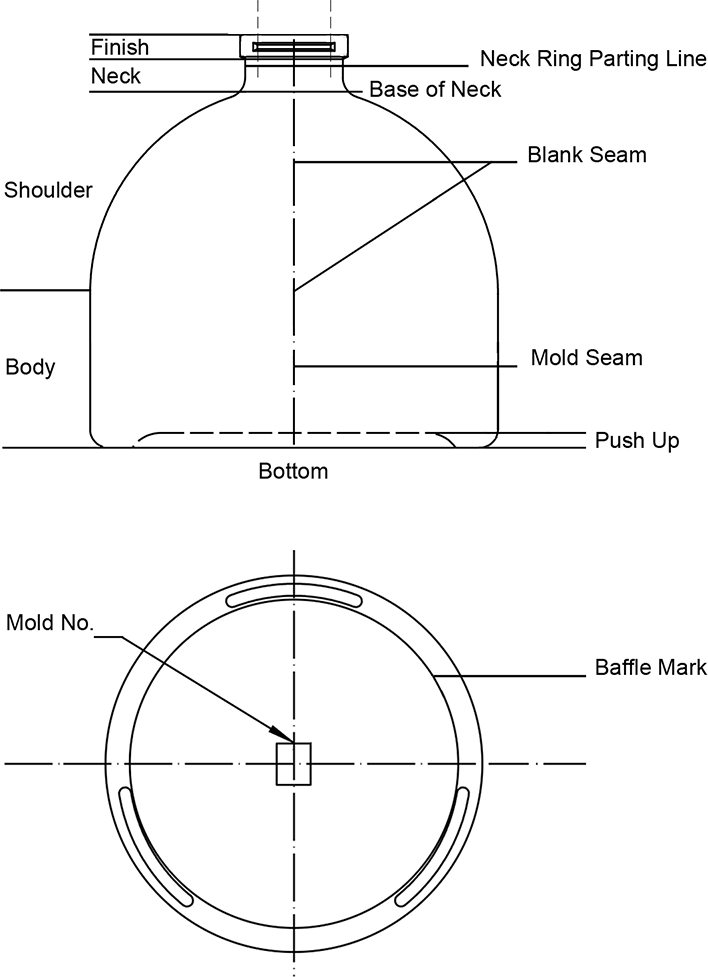

Surface Cracks: Surface cracks which occur on or near the parting line between the neck and the finish.

Bent Necks: A neck where the finish is tilted to one side. Note: It can cause trouble on the filling line and should be corrected at once.

Sunken Shoulders: A shoulder which is not fully blown up.

Thin Shoulders: A shoulder which has a thin section.

Black Spots: Small black spots in the bottle. May appear on the sidewall or base.

Blank and Blow Mold Seam: Seams which are relatively large, extending from the shoulder to the bottom of the bottle. Blank seams tend to veer off from the mold seam.

Bulged Sides: The sides of a bottle (usually panel shape) which are pushed out.

Sunken Sides: The sides of a bottle (usually panel shape) that are not fully blown up or may have sunk after release from the blow mold.

Wrinkles: A lap or fold on the outside of the bottle (can also be found in the finish).

Bubbles: Strings of small bubbles or diameter is more than one millimeter bubble in the bottle.

Uneven body: Uneven sidewall thickness.

Uneven bottom: A localized thick area at one side of the bottom.

Rocker Bottom: A bottom which has sagged so that the container is unstable when placed on a flat surface.

Shear Marks: A C-shaped mark in the glass, attributable to the action of the shears.

Scuffed Baffle Marks: The baffle mark is Scuffed and distorted, and it can scratch fingers.

Moved Baffle Marks: The baffle mark has swung to one side and is not central in the bottom of the container.

If you have any questions or inquiries, Our sales department supports you with all questions about our products and services. We are happy to hear from you!

Email: sales@henkaul.com

Whatsapp: +86 187-9542-5696